Industries

Synergy effects through knowledge transfer

Originally specialists on production lines of paper- and hygiene articles, we were then able to apply our experiences on new fields, for instance on packaging technology. Additionally, our clients appreciate our expertise in the fields of machines and equipment as well as in general mechanical engineering.

Technologies

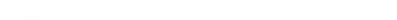

Unwinding material

Many applications request the transformation of roll material to an end product. We have a vast experience in the construction of unwinding axles, automatic splicers and material buffers. This facilitates for instance a roll change without resulting in any machine downtime.

Feeding sheets

A tricky task: the fedding of cuts and sheets from a stack. Our know how helps clients with the design and sizing of structural components.

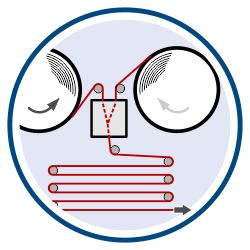

Transport of materials or products

In case of frictional connection between two transport belts or via suction belt conveyors: We have ample experience in the development of customised solutions for product specific transport tasks.

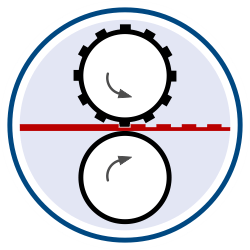

Embossing materials

Often different materials, like tissues, need to be embossed in the process of joining or for decoration. The design of the embossing unit and partly also of the embossing patterns requests a specific know how that we like to invest into projects.

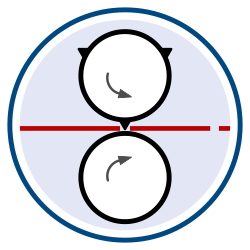

Cutting materials

There is hardly a production line that operates without the function of „cutting“. Cutting applications often carry along difficulties when applying strips of material. Whether rotary or linear cutting methods – our expertise leads to solutions that work!

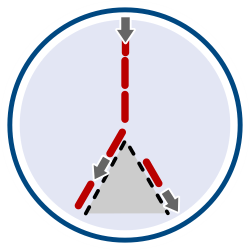

Folding materials or products

Folding operations can be handled differently: purely mechanical or with vacuum support. We conceptualise and help with the construction.

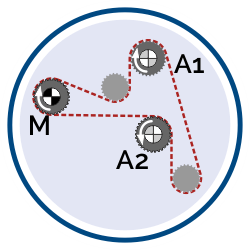

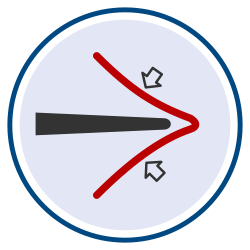

Splitting of product flows

An increase of production output often demands for a splitting of product flow with regards to consequent processing. But also product specific features can impact on a distribution to different sections of the production line. Varying with application and product we develop made to measure splitting functions.

Diverting of product flows

Spatial conditions in the production hall, but also conditions of the production process itself often necessitate a diversion of product flows. We are happy to support with creative, functional solutions.

Counting and grouping of products

Before packaging of products the product flow often needs to be portioned into package units. Or alternatively there is a hand over to the packaging process. Corporate Engineering has a profound knowledge in the individual design of machines that count and group products.